CNC Milling

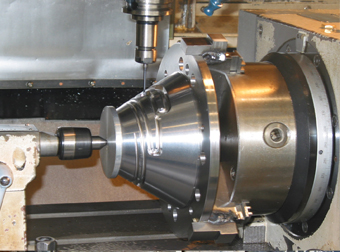

It is made up of 14 CNC machining centres, eight of which have a palletised table for the manufacture of large series of parts. 4 of these machining centres are prepared with 4th axis, which allows us to manufacture spindles, circular cams…, and with high resolution in data reading for perfect finishes in 3D surface machining.